Summary:PPH pipe shearing is the basic process of manufacturing pipe parts, including pipe cutting, port shape punching, punchin...

PPH pipe shearing is the basic process of manufacturing pipe parts, including pipe cutting, port shape punching, punching and incision. Pipe shearing is a stamping separation process. Compared with plate shearing, due to its own shape (hollow section) characteristics, in order to prevent the pipe wall from being flattened during shearing, the technological measures taken are more complicated. Manufacturing has also put forward higher requirements. Compared with machining cutting, pipe shearing is suitable for mass production due to its fast processing speed and high production efficiency. Therefore, it has a wide range of application prospects, but because the pipe shearing process itself is more complicated, and it is not mature enough in technology. Therefore, the application in production is not extensive enough. This chapter mainly introduces various process methods and application scope of pipe shearing.

In the manufacture of pipe parts, the pipe must first be cut to obtain a pipe blank of the required length of the pipe fitting. There are two main methods of pipe cutting: machining and stamping. Mechanical processing includes sawing machine cutting, lathe cutting, grinding wheel cutting, etc. The advantage is that the quality of the cut surface is stable, but because of its low productivity, it is difficult to meet the requirements of mass production. Stamping has high productivity, but the tube wall is easily flattened when cutting, resulting in distortion and skew of the cut surface. If the common material is cut by the method of shearing the bar, the pipe must be flattened and cannot be used. Therefore, it is very important to take special technological measures to prevent the pipe from being flattened during shearing, so as to ensure that the quality of the cut surface meets the use requirements of the pipe fittings.

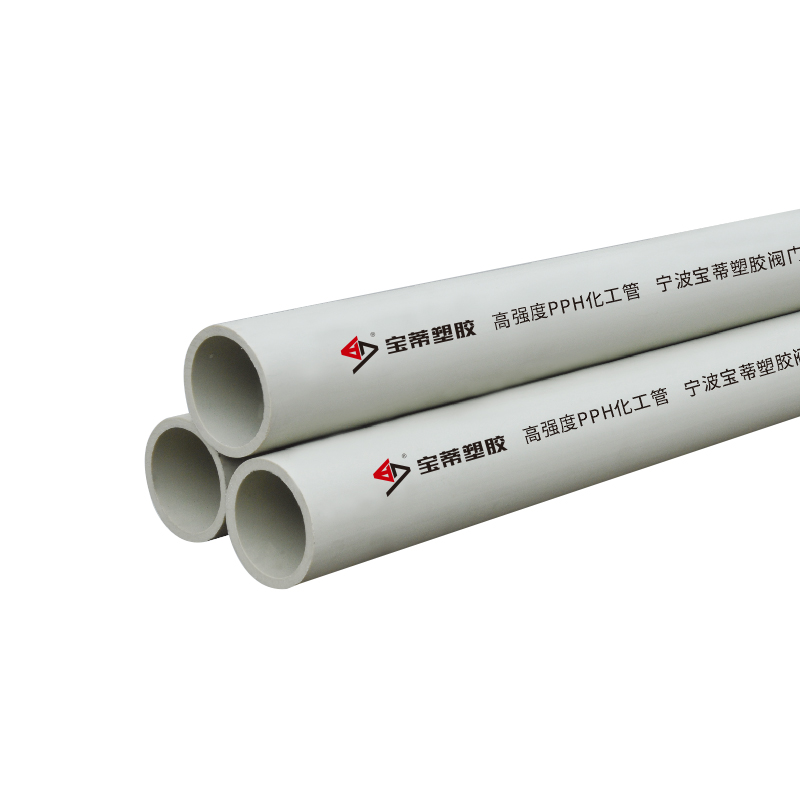

HOLLOW STRAIGHT PPH PIPE

Material: PPH

Size: DN15-300(1/2''--12'')

Pressure: 10bar

Head Code: Square

Other Material: CPVC, PVDF, UPVC, FRPP

Media: Chemical, acid, alkali, water, oil, food, waste water...

Standard: GB

Diameter: Dn15mm-300mm

Medium: Liquid/Gas/Water/Solution/Oil

Cross-Section Shape: Round/Semi-Circular

Temperature Classification: Medium Temperature Piping

MPa Classfication: Low Pressure Piping

Connection Type: Socket

Hardness: Hard Tube

Type: Thermoplastic Pipe

Color: Color

Hollow: Hollow

Shape: Round

Specification: DN: 15-400mm

Origin: China

HS Code: 3917230000

Usage: Drainpipe, Water Supply Pipe, Agricultural Irrigation Pipe, Chemical

Pipe Length: UPVC/CPVC-4m FRPP/PPH/PVDF-5m