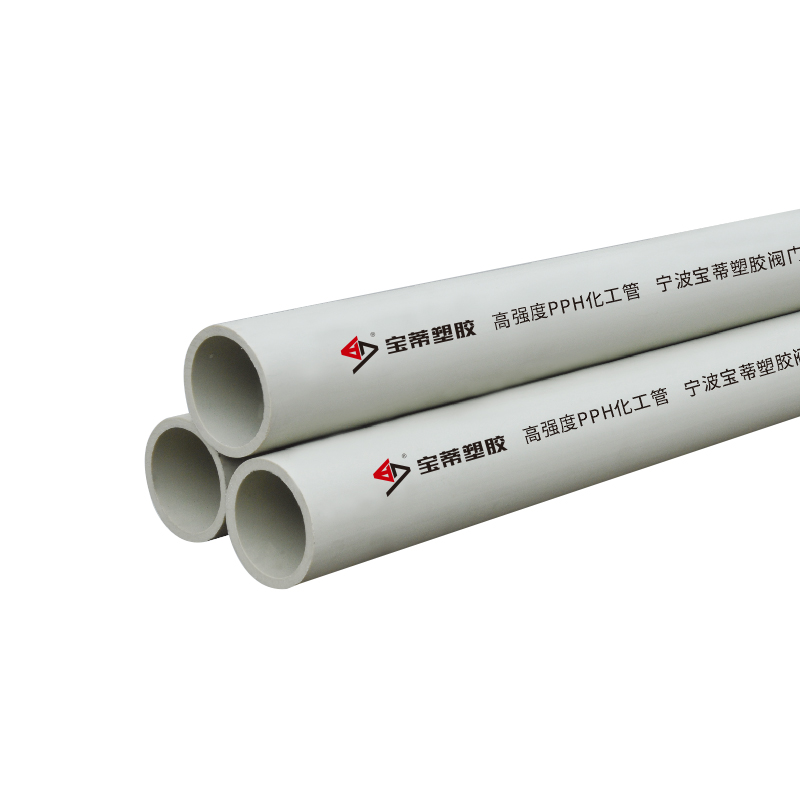

Summary:Uses and production requirements of PPH pipes

Specification for PPH Pipe

Execute HG 20539-92. Use the glass fiber modif...

Uses and production requirements of

PPH pipesSpecification for PPH Pipe

Execute HG 20539-92. Use the glass fiber modified polypropylene material treated with coupling agent to produce, generally used for the transportation of water and corrosive liquids. The sanitary function of drinking water pipes conforms to the provisions of GB/T17219. PPH pipeline products are mainly suitable for sheet pickling and waste acid recovery and regeneration systems in steel mills. PPH pipelines can also be used in chemical, environmental protection, power plants, food processing and other fields.

PPH pipeline is actually an extension product of FRPP pipeline. First of all, its molecules are all β-crystallized, so its high temperature resistance and corrosion resistance are stronger than FRPP, but the price is much more expensive than FRPP. It is mainly used in steel mills for pickling. aspect. FRPP and PPH are 80% functionally identical. PPH pipe is light in weight, non-toxic and can be used in food processing, corrosion resistance, high temperature resistance, good structure and obvious high impact strength.

PPH is a high molecular weight, low melt flow rate homopolypropylene, it has a fine crystalline structure through β modification, which makes it have excellent impact strength even at low temperatures, increased hydrostatic strength, and improved resistance to Chemical function. According to the characteristics of PPH materials, the production of PPH pipes and plates as corrosion-resistant equipment is widely used in chemical, metallurgical and electronic fields. PPH pickling tank and electrolytic tank, which are economical and durable, reduce equipment protection, extend service life, and have superior functions.

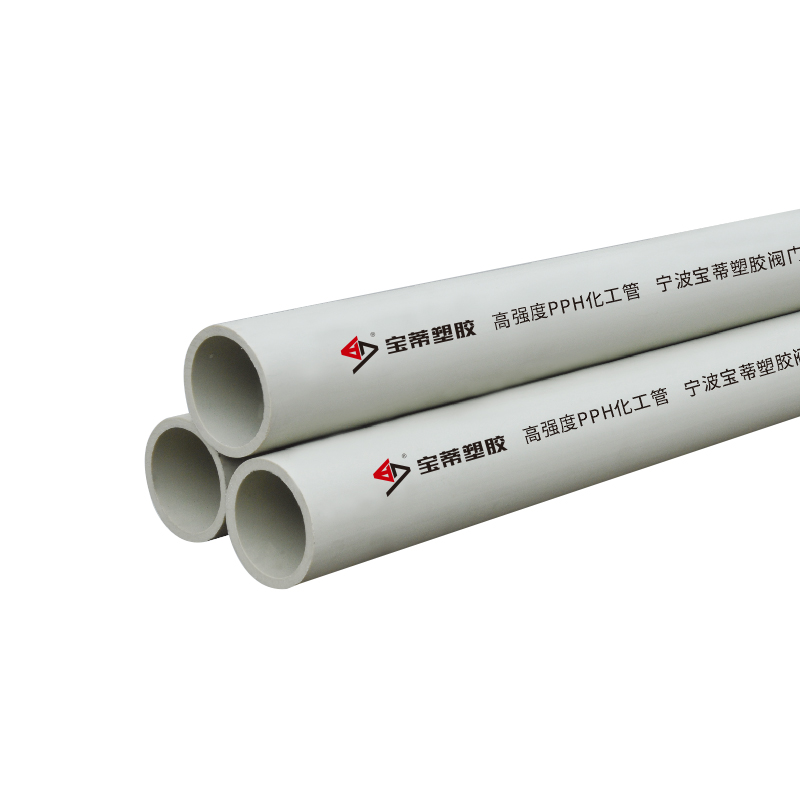

PPH pipeline features

Hygienic and non-toxic: This product is a green building material and is used in drinking water pipeline systems. The hygienic indicators meet the requirements of GB/T17219. Low temperature resistance: The low temperature embrittlement temperature of polyethylene is (-70 ℃), under normal conditions, no special protection measures are required for construction, and construction is convenient in winter. The impact resistance is good, and the tube will not be brittle. Corrosion resistance and no scaling: PE molecules have no polarity and have good chemical stability. Except for a few strong oxidants, most chemical media do not damage them. It does not breed bacteria and does not scale, and its flow area will not decrease with the increase of operating time.