Summary:The main function of the PVDF pipe tractor is to provide a certain traction force and traction speed for the melt tube b...

The main function of the

PVDF pipe tractor is to provide a certain traction force and traction speed for the melt tube blank coming out of the machine head, to overcome the friction force generated during the cooling process, so that the pipe material can be drawn out from the cooling and setting device at a uniform speed, and passed through Adjust the pulling speed to adjust the wall thickness of the PVDF pipe.

The tractor should be able to meet the needs of clamping pipes of various diameters, and it should be able to steplessly and smoothly change speed within a large range (the speed regulation range is usually), because one tractor should be used for the production of pipes with different diameters and different wall thicknesses. ; To provide enough traction, and the clamping force of the tractor to the pipe can be adjusted; so that the thick-walled pipe will not be permanently deformed, on the other hand, there should be enough tension to produce thick-walled pipes; the traction speed is quite large The speed is kept stable within the range of the traction speed, and the pulsation of the traction speed will cause bamboo knots on the surface of the PVDF pipe. There are two main types of traction machines: crawler type and belt type.

The selection of the traction device should consider the following factors:

The larger the outlet width of the PVDF pipe diameter, that is, the free passage of the traction device should be 50mm larger than the larger outer diameter of the pipe diameter to be conveyed;

Tube Wall Thickness and Hardness Low-hardness and thin-walled tubes require several long crawler tractors. The traction unit with two tracks uses rubber pads and rubber belts with low surface hardness;

Traction speed and traction There should be a margin of about 20%-25% for traction speed and traction.

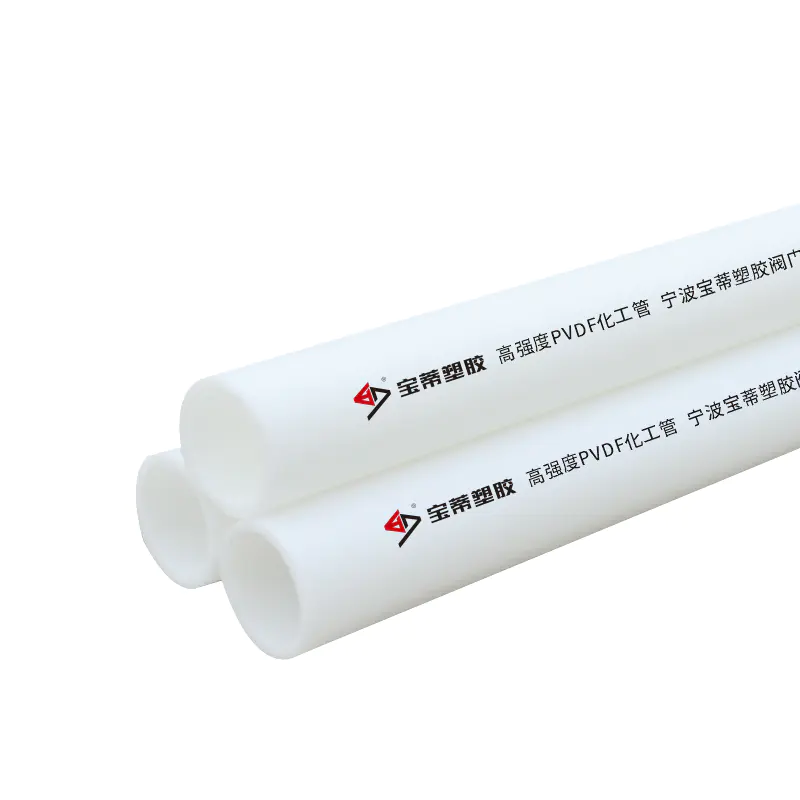

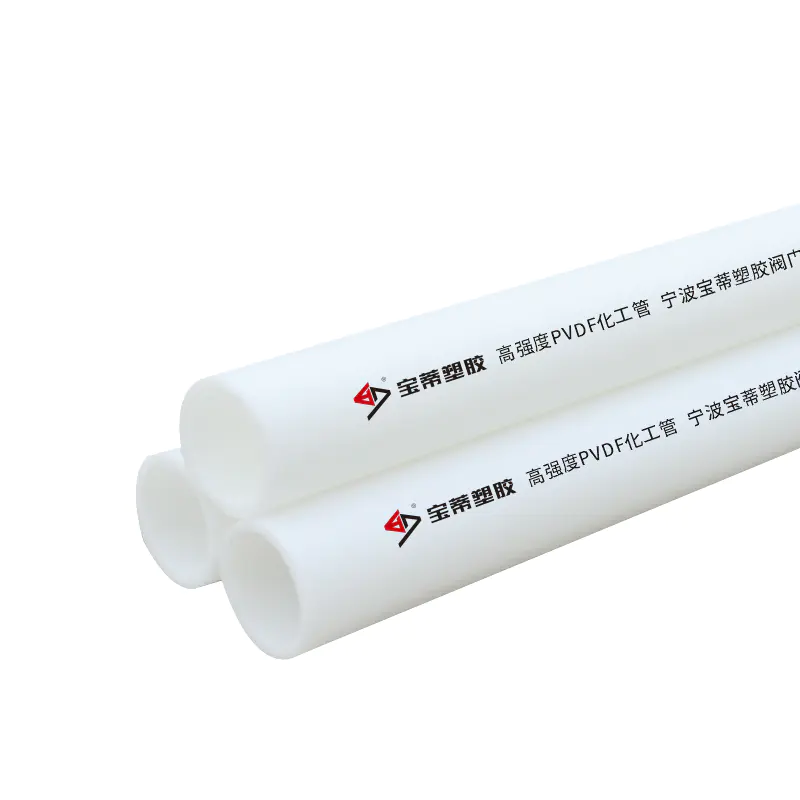

TUBE PN10/PN16 THERMOPLASTIC PVDF PIPE

Material: PVDF

Size: DN15-300(1/2''--12'')

Pressure: 10bar

Other Material: CPVC, UPVC, PPH, FRPP

Media: Chemical, acid, alkali, water, oil, food, waste water...

Standard: GB

Diameter: Dn15mm-300mm

Medium: Liquid/Gas/Water/Solution/Oil

Cross-Section Shape: Round/Semi-Circular

Temperature Classification: Medium Temperature Piping

MPa Classification: Low-Pressure Piping

Connection Type: Socket

Hardness: Hard Tube

Type: Thermoplastic Pipe

Color: Color

Hollow: Hollow

Shape: Round

Specification: DN: 15-400mm

Origin: China

HS Code: 3917230000

Usage: Drainpipe, Water Supply Pipe, Agricultural Irrigation Pipe, Chemical

Pipe Length: UPVC/CPVC-4m FRPP/PPH/PVDF-5m

Working temperature: PVDF- ~40ºC-+120ºC